NESHAP 319 - Aerospace

WHAT IS THE NESHAP 319 STANDARD?

The National Emission Standards for Hazardous Air Pollutants (“NESHAP”) established specific standards, tests and procedures for aerospace manufacturing and rework facilities. BoothFilterStore.com offers several filtration choices to assist in your compliance with NESHAP rules and regulations. Specifically, our filters are designed to comply with the Environmental Protection Agency’s (“EPA”) test protocol known as Method 319.

Method 319 is a testing protocol in which potassium chloride and oleic acid are substituted for chromate paint. These chemical substances attempt to simulate dry and wet overspray characteristics of chromate paint. This testing protocol verifies that an air filtration system has met minimum efficiency requirements, under laboratory conditions, utilizing potassium chloride and oleic acid.

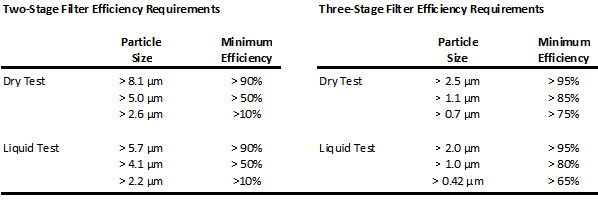

If a spraybooth existed before 1999, its filtration system must comply with the two-stage standard, and if it was built after 1999, it must comply with the three-stage standard.

The tables below show the required compliance efficiency levels by micron size.

VIEW 3-STAGE NESHAP FILTRATION SYSTEM

Regulations pursuant to Method 319 also state:

“For a paint arrestor system or subsystem which has been tested by this method, adding additional filtration devices to the system or subsystem shall be assumed to result in an efficiency of at least that of the original system without the requirement for additional testing. For example, if the final stage of a three-stage paint arrestor system has been tested by itself, then the addition of the other two stages shall be assumed to maintain, as a minimum, the filtration efficiency provided by the final stage alone.”

Simply put, as long as one portion of your filtration system meets the requirements of Method 319, you are able to use a wide range of additional filters to support and/or extend the operating life of the filter that complies with EPA Test Method 319.

Additional NESHAP 319 Requirements Include: Monitoring

- Maintain systems in good working order

- Install differential pressure gauges across the filter banks

- Continuously monitor pressure drop across the filter banks

- Read and record the pressure drop across the filter banks once per shift

- Shut down operation and take corrective action when pressure drop exceeds or falls below manufacturer’s recommendation

- Shut down operation if scheduled maintenance has not been performed

Record Keeping

- Prepare a startup, shutdown, and malfunction plan which includes:

- Operation and maintenance criteria

- A standardized equipment operation and maintenance checklist

- Procedures for identifying and reporting malfunctions

- Procedures to prevent malfunctions due to preventable conditions

- Operate all equipment in accordance with a developed control plan and manufacturers' specifications for installed systems/products

Report Submission

- Semiannually submit detailed compliance report

- Semiannually report all times when topcoat or primer operation was not immediately shut down should pressure drop across a dry particulate filter system be recorded outside specified limits

- Annually report the number of times the pressure drop for each dry filter was outside specified limits, even though the system was properly shut down in accordance with the operating plan